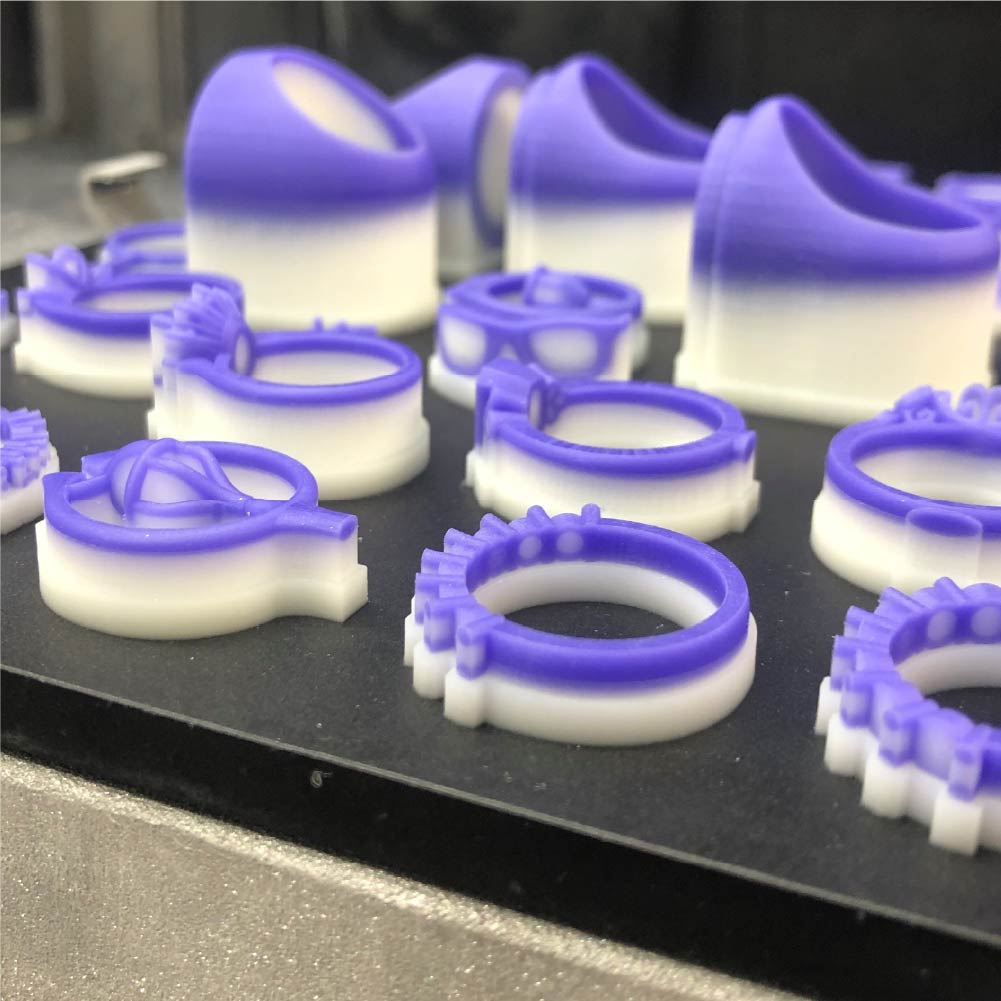

About CastingFor nearly 50 years, Morris and Watson has combined impeccable craftsmanship with advanced technology to produce high quality cast jewellery products for clients throughout the world. Morris and Watson offers complete jewellery casting services with expertise that spans the entire spectrum of jewellery casting. Products and services include; general jewellery casting, mould creation and cutting, 3D printing and CAD design. With a large and well equipped casting department, the Morris and Watson casting team can handle a range of casting projects, from one-of-a-kind pieces for bespoke jewellery manufacturers to large runs for corporate clients. All castings are produced using alloys developed in-house, which ensures a high quality and accurate casting product, delivered on time. Click here to view our casting alloys. |  |

3D Printing & Casting |  Mould Creation |  Cast Your Waxes |  CAD Design |

| Consistent High Quality With decades of casting experience, castings produced with our processes and skilled personnel enables us to significantly reduce your finishing time and therefore reduce your costs. | |

| Competitive Prices We are precious metal refiners so we can offer highly competitive prices. | |

| Sprues Removed All sprues will be cut off at 3mm, unless otherwise specified. This reduces your finishing time and lessens your overall cost. | |

| Multi Sprueing An effective way to further reduce your costs. Contact us to check if this service will suit your business. | |

| Rubber & Cold Liquid Moulding Standard rubber moulding and cold (silicone) moulding for master patterns that can't withstand heat produced in the vulcanising process. | |

| 3D Printing The latest 3D wax printing fleet to ensure accurate and detailed print and cast quality. Upload to get an instant quote and to place your order. | |

| CAD Design Our CAD design team are also experienced jewellers giving you confidence when we create your CAD designs. |

Casting Processing Times |

| Service | Lead Time * | Details |

|---|---|---|

| 3D print wax and cast (Customer supplied STL) | 5 Working days | STL file must be received by the casting department no later than 3pm New Zealand (NZST/NZDT) time or 12pm for Australia (AEST) |

| Cast from customer supplied wax (single) | 5 working days | Single customer wax for casting (casting multiples of the same item will require mould creation) |

| Cast from existing mould | 5 working days | Wax injection and casting from customer supplied or Morris and Watson stored mould |

| Create mould from master pattern and cast | 7 working days | Customer supplied master pattern or wax needing mould creation and casting |

| Create mould from STL and cast | 10 working days | Customer supplied STL file needing printing, mould creation and casting |

| * Please note: lead times are taken from the day an order is received by the casting department to when it is dispatched, timeframe does not include shipping | ||

|

|