3D PrintingMorris and Watson prides itself on being the leaders in advancing technology within the jewellery casting trade. Morris and Watson are constantly upgrading and investing in new products, services and technology such as state-of-the-art 3D printers. This allows for the ability to produce your models specifically to your needs, with precision and accuracy. This 3D Printing technology means Morris and Watson can capture the finest detail not possible with traditional methods and take your work to the next level. Understanding that time, cost and quality are essential to all clients, Morris and Watson have invested significantly in the latest in 3D printing technology. Morris and Watson can now print models faster and more accurately in less time. This means cost savings can be passed on to clients, with prints starting from $20. The standard production time for printing and casting 3D STL files is 5 working days (plus shipping). UPLOAD, QUOTE AND ORDER YOUR STL NOWTo make it easier for you to budget for print and casting costs, Morris and Watson have created an online system for you to upload your 3D model and get an instant quote. From there you can sign up (or sign in) and place your order (no login required to upload and quote). |  |

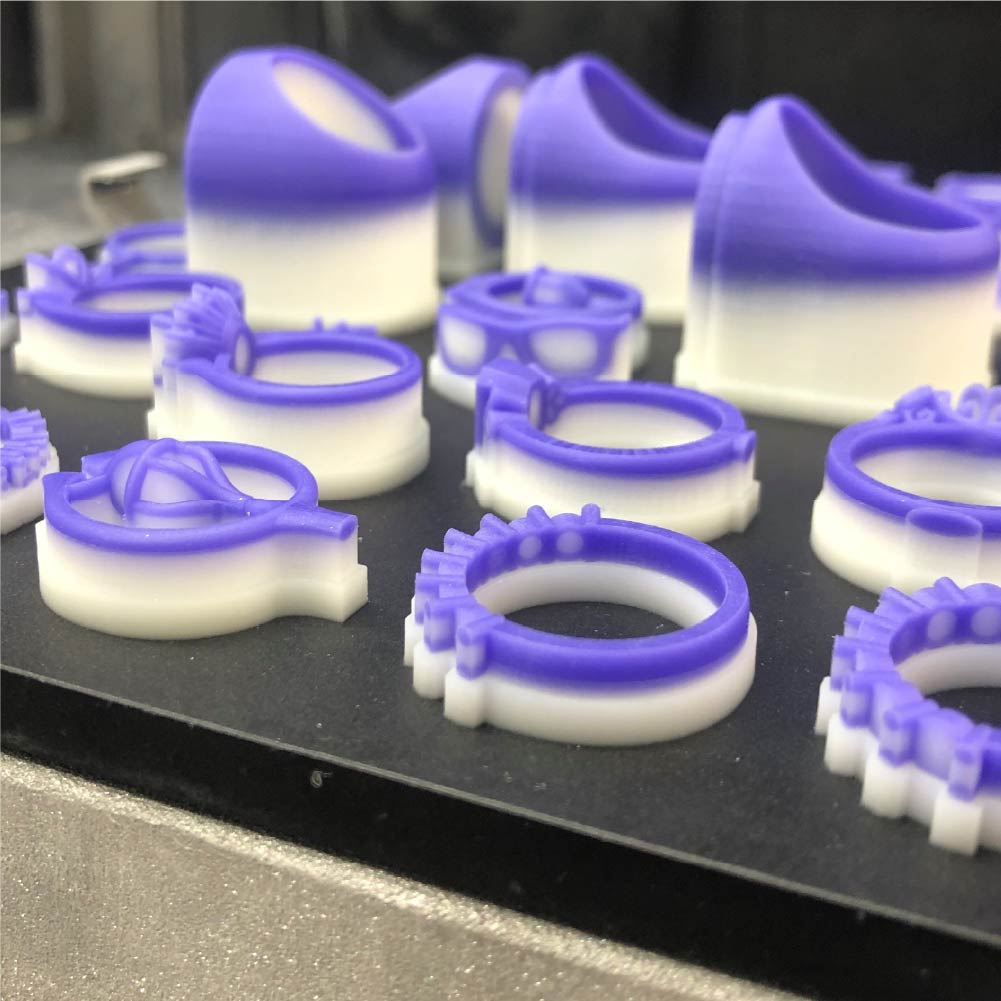

THE 3D PRINTERS WE USEWe use both castable wax and castable resin printing technologies. Both materials produce excellent results but can have slight differences in the outcomes, depending on the design aspects of the 3D file. Both materials are further processed in a similar way, where they are encased in investment (plaster-like material) to then be vapourised, leaving a void impression of the model (called “burning out”). Molten casting alloy is then injected into the voids to create the final castings. Castable WaxCastable wax printers use liquid wax to create a model by depositing layers of liquid wax on a print build plate. The printers work like an inkjet printer, injecting each liquid wax layer in a x-y coordinate (e.g. side-to-side for each line) until all the layers for a model are built. As castable wax is more fragile than resin, models are also printed with support wax layer Castable wax has excellent self-supporting qualities, predictable burnout characteristics and tends replicate finer detailed aspects (such as makers marks and hallmarks in shanks) better than resin. |  |

| Castable ResinCastable resin printers use liquid resin and UV light to create a model. The build plate is submerged in a tank of the resin. A light source then shines onto the build plate, curing the resin into the shape of each layer of the model. The build plate then moves away from the light source to position itself ready for the new layer. The build plate is generally positioned over the resin tank with the models hanging from it, with the light source at the bottom of the tank. Castable resin has excellent surface qualities (to allow for faster clean up) and for some model, can allow for finer detail that wax. Which material is best?The best material depends on each model. Resin is preferrable for smaller models such as stone settings where minimum clean up and reduced material removal is prioritised. Wax is preferrable for more complex designs or designs with many unsupported aspects. Fine tuning of printer configurations and model orientation on the build plates are also considered. Regardless, both materials will produce excellent quality castings. Our experienced casting team will determine which method is best for your design, prioritising a successful and high quality casting the first time. Contact your local Morris and Watson office if you have any questions. Our experienced Customer Service team are always happy to help and answer your questions. |

|

|